Bead Blast Cabinets

We offer a range of quality Australian manufactured steel cabinets for various types of finishing operations. Cabinets from 800mm - 1800mm wide with suction or pressure blast and standard or reverse pulse dust collectors available. It would be easier to consider cleaning, peening and finishing from the single perspective of surface preparation, but that is only part of the story. We believe that each function must be seen as a carefully fashioned part of the total plant operation system. We therefore strive to give each of our products a distinctive, precise balance in engineering design. In addition, we offer a broad variety of options and accessories, we recognise that industrial requirements are so numerous and complex that just one or two designs would not suit all applications. Our engineering ensures that you are receiving the most advanced designs available.Summary

There are two techniques of enclosed cabinet blast cleaning, Suction and Pressure Blast, differ sufficiently enough to provide a wide choice of qualities and characteristics for selection of the ideal cabinet for your requirements.

Suction Blast combines the advantages of minimal compressed air requirements, standard mesh media and simple operating technique.

Pressure Blast offers the ultimate in blasting to provide an accelerated rate of cleaning, 3-4 times faster than suction blast.

Both types require Dust Collectors in order to make our blasting system more efficient. We have developed two integrated dust collector designs. These finely balanced units provide maximum cabinet visibility and efficiency.

Features

CS Suction Blast Cabinet

Abrasive is fed to a standard 8mm Tungsten Suction Gun from the cabinet hopper. The principle is a venturi action (suction) blasting using a foot operated on/off pedal, connected to the suction gun. This concept is ideal for general light blasting using a variety of fine to mediaum abrasives, e.g. No1 to 4 Glass impact spheres or Garnet 60/30.

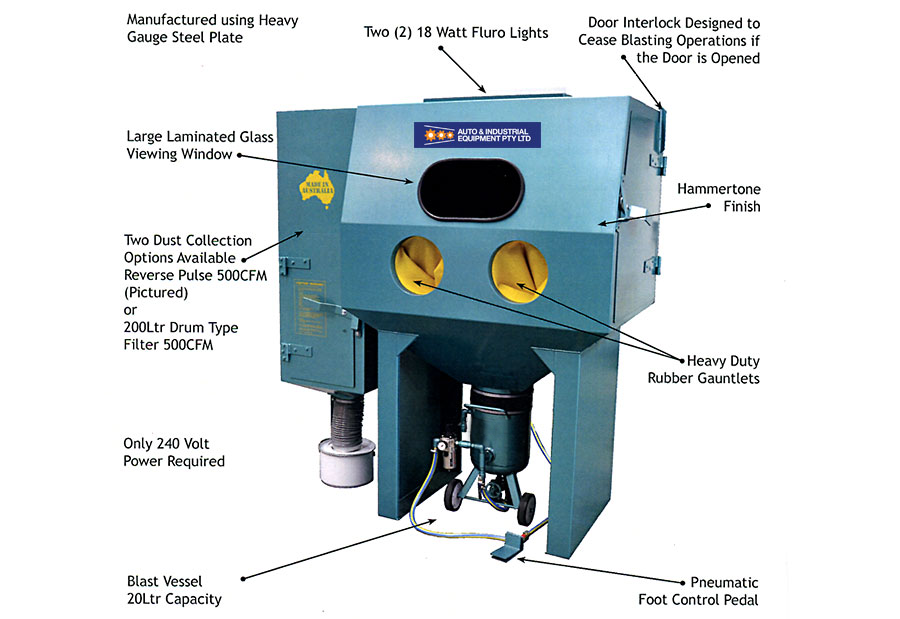

CP Pressure Blast Cabinet

Abrasive is fed to a standard 4.8mm Tungsten Nozzle from a 20L pressure vessel fitted below the cabinet hopper. The principle is low to high pressure blasting using a foot operated on/off pedal. This concept is ideal for production type blasting using a variety of fine to medium and coarse abrasives, e.g. No 1 to 4 Glass impact spheres, Garnet 60/30 and steel grits.

Gloves

Heavy duty 680mm rubber gloves.

Work Floor

The work floor is steel perforated plate.

Reverse Pulse and Drum Type Dust Collectors

All models are supplied with 200L Drum Filter as standard. A Reverse Pulse Cartridge filter can be supplied as an option.

Specifications

Technical Specifications

| Cabinet Models CP & CS | CS1000 | 800 | 1200 | 1500 | 1800 |

| Overall Height | 2200* | 2200* | 2200* | 2600* | 2900* |

| Overall Width | 1050 | 1400* | 1800* | 1600* | 1900* |

| Overall Depth | 650 | 900 | 1000 | 2100* | 1800* |

| Work Chamber Height | 1010 | 900 | 850 | 1100 | 1800 |

| Work Chamber Width | 1000 | 800 | 1200 | 1500 | 1800 |

| Work Chamber Depth | 600 | 800 | 900 | 1200 | 1200 |

| Door Opening Height | 850 | 825 | 775 | 1025 | 1025 |

| Window – Shatterproof Laminated 450x240mm | 1 | 1 off | 2 off | ||

| Lighting – Twin 18 Watt Fluorescent | 1 | 1 off | 2 off and 2pr gloves | ||

| Cabinet Models CP & CS | CS | 800 | 1200 | 1500 | 1800 |

| Doors with interlocks | RH side | RH side | RH side | Both sides | Both sides |

| Note | Requires Operator Platform | ||||

| Dust Collector Motor | 750 Watt | ||||

| Voltage | 240 Volt, three pin plug is wired to the light and Dust Collector. | ||||

| All Steel Construction | 2-3 mm | ||||

| Air Requirement | Min: 8L/sec (16cf/m) – Max: 21L/sec (45cf/m) | ||||

*Dimension includes 600mm for Reverse Pulse dust collector / take off 600mm for Drum Type

Optional Accessories

| Turn Table | 630 mm diameter |

| Blow Off Gun | 1 M hose |

| Water trap and regulator | 12 mm on Pressure Blast Cabinets |

| Roll In Roll Out Table | 250 kg and 500kg (800 & 1200 cabinets 630mm dia., 1500 & 1800 cabinets 1000mm dia.) |

| Tumble Basket | 225 dia. x 200mm & 457 dia. x 400mm |

Applications

- General Automotive

- Engine Reconditioning

- Excavation Workshops

- Mining

- Truck Workshops

- Manufacturing

- Parts Painting and Preparation

- Rust Removal

- Paint Removal

- Glass Etching

- Aviation

- Electrical

- Marine